|

[ Home ] [ Up ] [ UCEP Feedback Page ] [ Table of Contents ] [ SEARCH ]

|

|

|

Description of the GT Aquatic Center PV System

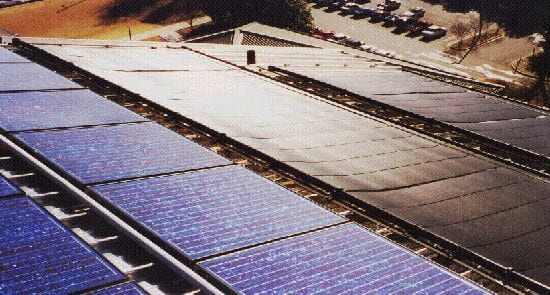

Description of the Georgia Tech Aquatic CenterGeorgia Tech Aquatic Center was the site of the aquatic events for the 1996 Olympic The Aquatic Center has 4000 permanent seats. If you saw the Center on TV during the The photovoltaic (PV) array on the roofThe array consists of 2,856 PV modules, each one containing 72 multicrystalline silicon The rated power of the 2,856 module array is 342 kW (DC). At the time of the 1996 The PV system’s power conditioning system (PCS)Next to the PV modules themselves, the most important part of the PV system is the In a PV system, whether a large DC array with one central PCS, like the Aquatic Center

Technical specifications of the PCS:

The AC output of the PCS is fed directly into the grid at the main service entrance to The data acquisition system (DAS)Part of the reason this system is so useful to Georgia Tech is that it is being

Manufacturers of Aquatic Center PV system components

A word on the economics of PV and this systemWe’ve been asked many times whether this system will pay for itself in its lifetime, Another factor which must be considered is the environment. Most of us in the Another economic question related to the environmental issue just discussed is that One final economic note on renewable technologies: there are two fundamental On the research front, it is hoped that the availability of a system like this in such The Solar Thermal System on the roof of the GTAC

This shot shows a portion of the solar thermal system along with some of the PV The solar thermal system is backed up by auxiliary systems which include four large For more information:

AcknowledgementsThis project was sponsored by Georgia Tech, the U.S. Department of Energy, and Georgia Power Company. We gratefully acknowledge

|